The shoe

Everything began with a workshop

Although Henderson Baracco’s workshop was started 80 years ago, it is still in constant evolution.

With our roots firmly in all-Italian artisanal tradition, we preserve the solidity of a long-established company, designing products perfected by constant research.

In a balance between memory and modernity, we traverse the present with comfort and timeless style.

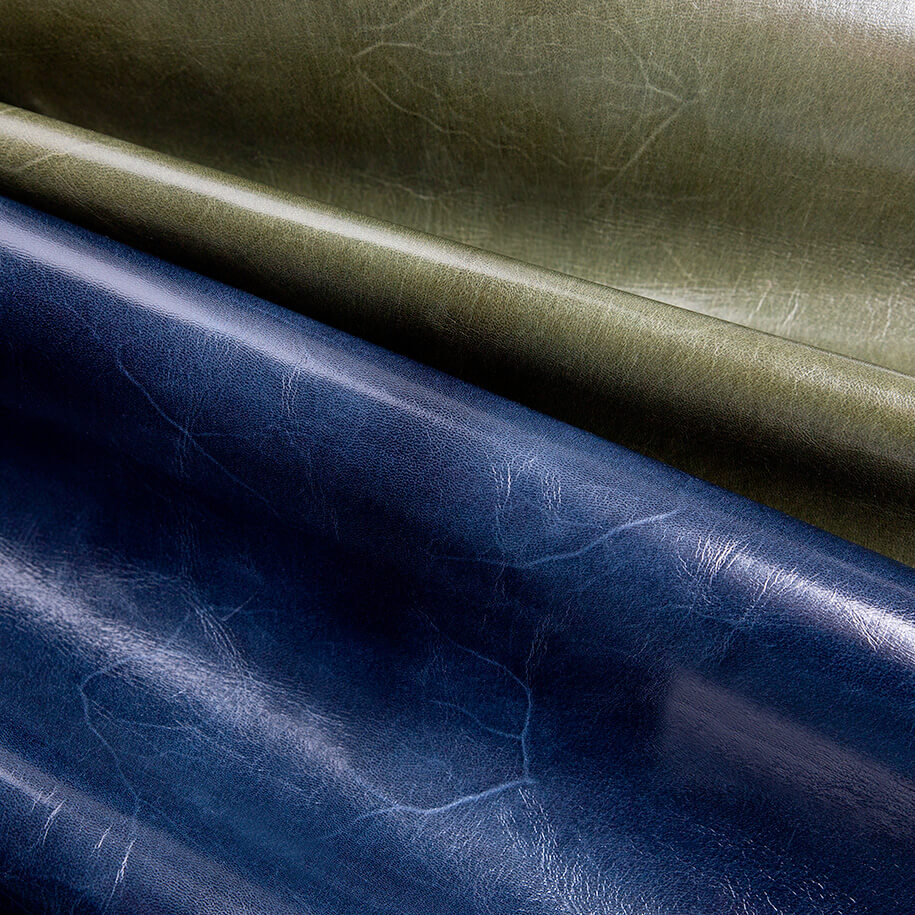

Materials

The first, vital ingredient. We carry out a careful selection of raw materials to create durable products able to gratify the senses with their softness, scents and quality.

The steps in making a shoe

Each Henderson Baracco shoe takes four weeks to make.

A process that we monitor at every stage of its creation – from production of the last to stitching the sole, through to the final finishing and polishing stages. Skilled, fast, expert hands are guided by the mastery handed down from generation to generation. They are hands that work with old tools, worn through use, and precise gestures that are repeated today as yesterday.

1. Sketch on paper

The initial idea, the guidelines. Simple lines that evoke freshness and sophisticated modernity

2. Blake Sewing

This is a traditional, complex and painstaking process, which involves stitching the sole to the leather upper and which, unlike ordinary processes, guarantees greater durability and flexibility

3. Finishes

The keen eyes and expert hands of our craftsmen supervise every single detail. Meticulous attention to detail and care reserved for finishing to meet your demands with empathy and precision

4. Finishing and polishing

Trimming the sole, colouring and brushing the shoe, polishing the upper. Small steps, one after the other, essential to create a product that is unique, beautiful, elegant – but above all, comfortable

Blake Stitching: the process that is our hallmark.

Not only tangible proof of sartorial luxury, but also a link between the manufacturing art of the past and the quality of the present.

Blake construction is a painstaking, complex process, now almost impossible to find. It consists in the creation of a single hand sewn seam that holds the sole, lining, upper and insole together. The result? More durable and flexible shoes, with evident uniqueness.

Maintenance and Care

Each Henderson Baracco shoe is a unique piece, to be preserved with love. If you follow our advice, your shoes will last forever

After each wear:

Leave the shoes to air. Preserve the shape with a cedar wood shoe tree.

Recommendation for everyday care:

Do not expose the shoes to sources of direct light or heat.

Carry shoes in the original bag, which can also be used to clean the leather

Maintenance

Apply cream with a high wax content to the clean shoe. Choose a colour similar to the upper and do not use waterproof or self-shining products.

Use a neutral polish to clean the soles and hidden areas.

After brushing the upper, apply cream with a cloth and let it dry.

Polish the shoe with shoe tree inserted using only brushes with soft bristles.

Suede shoes:

Suede shoes require more special care. Use a rubber bristle brush to remove any stains.

Wipe with a damp sponge, being careful not to spread the dirt.

Rub with fine grit sandpaper (type 00) and brush to revive the nap